Regular Reverse Osmosis Membrane

HG Series Regular Reverse Osmosis Membrane

Performance Feature

The HG Series Regular Reverse Osmosis Membrane Element of AMESTEC is specially developed for the Chinese market with the high cost performance reverse osmosis membrane components. It has a stable desalination rate and water yield, pollution-resistant, easy to clean, and ensure a long-term and stable operation of the system, reducing operating costs.

Product Specifications

Table 1 Membrane Element Parameters

|

Product |

Effective Area ft2(m2) |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-DS01 |

85(7.9) |

2400(9.1) |

99.5% |

|

HG-DS02 |

90(8.4) |

2550(9.7)

|

99.5% |

|

HG-DS01-AD |

85(7.9) |

2600(9.8) |

99.5% |

|

HG-DS02-AD |

90(8.4) |

2750(10.4) |

99.5% |

|

HG-DS10 |

375(34.8) |

10500(40) |

99.5% |

|

HG-DS20 |

400(37.2) |

11200(42.4) |

99.5% |

|

HG-DS10-AD |

375(34.8) |

11500(43.5) |

99.5% |

|

HG-DS20-AD |

400(37.2) |

12500(47.3) |

99.5% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test condition: 2,000mg/L NaCl solution, 225psi operating pressure, temperature of 25℃, the recovery rate of 15%.

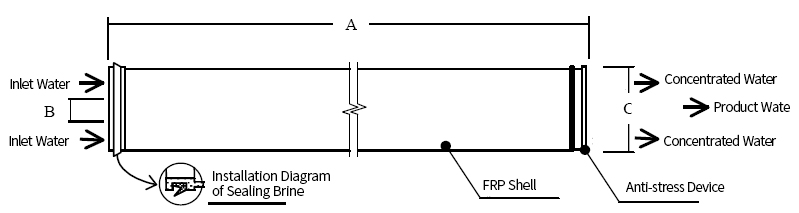

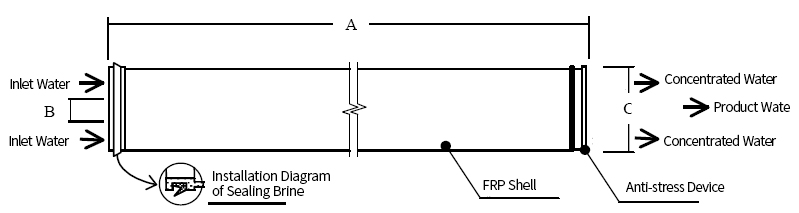

Membrane Element Figure

Limit Operation

Product Model |

HG-DS |

Max Operating Pressure |

600psi |

Typical Operating Pressure |

225psi |

Pressure Drop of Single Membrane |

<12psi |

Recovery Rate

|

15% |

Max Operating Temperature |

50℃ |

Max Cleaning Temperature |

50℃ |

PH Range of Continuous Working |

4.0-11.0

|

PH Range of Cleaning |

2.0-11.5

|

Allowable Max Contents of Residual Chlorine |

500ppm-h |

Inlet Water |

NTU<1 |

SDI<5 |

Storage Conditions

Before the first use, all membrane elements must be stored under the original packaging conditions.

Store in a cool, dry and the place where is not directly exposed to sunlight or artificial lighting. Storage temperature stays at 0℃ to 30℃, and the longest storage time is 6 months.

HG Series Large Flux and Ultra-Low Pressure Membrane

Performance Feature

HG series large flux ultra-low pressure composite reverse osmosis membrane, under the same amount of water production, the operating pressure is 1/3 lower than that of HG-DS series membrane components, while maintaining the advantages of high desalination rate and low total cost. It saves a lot of energy, which makes the reverse osmosis system easier to promote and accepted by customers.

Product Specifications

Table 1 Membrane Element Parameters

|

Product |

Effective Area ft2(m2) |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-SE01 |

85(7.9) |

2400(9.1) |

99.0% |

|

HG-SE02 |

90(8.4) |

2550(9.7)

|

99.0% |

|

HG-SE03 |

85(7.9) |

2650(10.0) |

92.0% |

|

HG-SE04 |

90(8.4) |

2850(10.8) |

92.0% |

|

HG-SE01-AD |

85(7.9) |

2600(9.8) |

99.0% |

|

HG-SE02-AD |

90(8.4) |

2750(10.4) |

99.0% |

|

HG-SE03-AD |

85(7.9) |

2850(10.8) |

92.0% |

|

HG-SE04-AD |

90(8.4) |

3000(11.4) |

92.0% |

|

HG-SE10 |

375(34.8) |

10500(40) |

99.0% |

|

HG-SE20 |

400(37.2) |

11200(42.4) |

99.0% |

|

HG-SE30 |

375(34.8) |

11500(43.5) |

92.0% |

|

HG-SE40 |

400(37.2) |

12200(46.2) |

92.0% |

|

HG-SE10-AD |

375(34.8) |

11500(43.5) |

99.0% |

|

HG-SE20-AD |

400(37.2) |

12500(47.3) |

99.0% |

|

HG-SE30-AD |

375(34.8) |

12200(46.2) |

92.0% |

|

HG-SE40-AD |

400(37.2) |

13000(49.2) |

92.0% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test condition: 500mg/L NaCl solution, 115psi operating pressure, temperature of 25℃, the recovery rate of 15%.

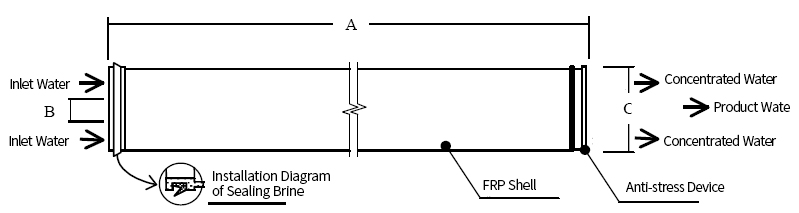

Membrane Element Figure

Limit Operation

Product Model |

HG-SE |

Max Operating Pressure |

600psi |

Typical Operating Pressure |

225psi |

Pressure Drop of Single Membrane |

<12psi |

Recovery Rate

|

15% |

Max Operating Temperature |

50℃ |

Max Cleaning Temperature |

50℃ |

PH Range of Continuous Working |

4.0-11.0

|

PH Range of Cleaning |

2.0-11.5

|

Allowable Max Contents of Residual Chlorine |

500ppm-h |

Inlet Water |

NTU<1 |

SDI<5 |

Information about Storage

Before the first use, all membrane elements must be stored under the original packaging conditions.

Store in a cool, dry and the place where is not directly exposed to sunlight or artificial lighting. Storage temperature stays at 0℃ to 30℃, and the longest storage time is 6 months.

HG Series Anti-fouling Membrane

Performance Feature

HG series anti-fouling membrane utilizes new membrane technology. The charge on the surface of the membrane is neutral and is hardly affected by the adsorption of the charged substances. It uses the widest inlet water channel in the industry, reduces the possibility of the membrane being fouled, and has an obvious cleaning effect.

Its main features are as follows:

- High salt rejection;

- Anti-pollution and stable operation;

High porosity, water yield and water quality.

Product Specification

Table 1 Parameters of Membrane

|

Product |

Effective Area ft2(m2) |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-LF01 |

85(7.9) |

2700(10.2) |

99.5% |

|

HG-LF02 |

90(8.4) |

2850(10.8)

|

99.5% |

|

HG-LF03 |

90(8.4) |

3000(11.3) |

99.5% |

|

HG-LF01-AD |

85(7.9) |

2850(10.8) |

99.5% |

|

HG-LF02-AD |

90(8.4) |

3000(11.3) |

99.5% |

|

HG-LF03-AD |

90(8.4) |

3150(11.9) |

99.5% |

|

HG-LF10 |

375(34.8) |

11800(44.7) |

99.5% |

|

HG-LF20 |

400(37.2) |

12500(47.3) |

99.5% |

|

HG-LF30 |

400(37.2) |

13000(49.2) |

99.5% |

|

HG-LF10-AD |

375(34.8) |

12500(47.3) |

99.5% |

|

HG-LF20-AD |

400(37.2) |

13000(49.2) |

99.5% |

|

HG-LF30-AD |

400(37.2) |

13500(51.1) |

99.5% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test Condition: Solution of 2,000ppm NaCl, 225psi of operating pressure, 25℃ of temperature, pH7, 15% of recovery rate.

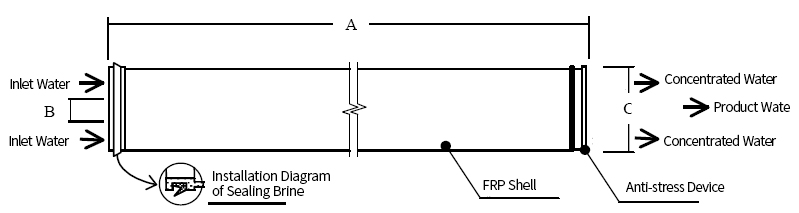

Membrane Element Figure

Limited Operation

Product Model |

HG-LF |

Max Operating Pressure |

600psi |

Typical Operating Pressure |

225psi |

Pressure Drop of Single Membrane |

<12psi |

Recovery Rate

|

15% |

Max Operating Temperature |

50℃ |

Max Cleaning Temperature |

50℃ |

PH Range of Continuous Working |

4.0-11.0

|

PH Range of Cleaning |

2.0-11.5

|

Allowable Max Contents of Residual Chlorine |

500ppm-h |

Inlet Water |

NTU<1 |

SDI<5 |

Information about Storage

Before the first use, all membrane elements must be stored under the original packaging conditions.

Store in a cool, dry and the place where is not directly exposed to sunlight or artificial lighting. Storage temperature stays at 0℃ to 30℃, and the longest storage time is 6 months.

Avoid backpressure on the water side of the product at all times, so as not to cause undesirable problems.

HG Series Ultrapure Water Membrane

Function and Identity

HG ultrapure water film element of AMESTEC has high desalination rate, high anti-pollution and high removal rate of boron, silicon, and germanium and so on, so that to avoid the fluctuation of effluent quality caused by influent water quality in EDI system. The chemical cleaning period of membrane element is long and the effluent quality is stable, which is suitable for ultra-pure water EDI system as desalination assembly in microelectronics industry.

Product Specification

Table 1 Parameters of Membrane

|

Product |

Effective Area ft2(m2) |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-CW01 |

85(7.9) |

2700(10.2) |

99.5% |

|

HG-CW02 |

90(8.4) |

2850(10.8) |

99.5% |

|

HG-CW01-AD |

85(7.9) |

2850(10.8) |

99.5% |

|

HG-CW02-AD |

90(8.4) |

3000(11.3) |

99.5% |

|

HG-CW10 |

375(34.8) |

11800(44.7) |

99.5% |

|

HG-CW20 |

400(37.2) |

12500(47.3) |

99.5% |

|

HG-CW10-AD |

375(34.8) |

12500(47.3) |

99.5% |

|

HG-CW20-AD |

400(37.2) |

13000(49.2) |

99.5% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test Condition: Solution of 2,000ppm NaCl, 225psi of operating pressure, 25℃ of temperature, pH7, 15% of recovery rate.

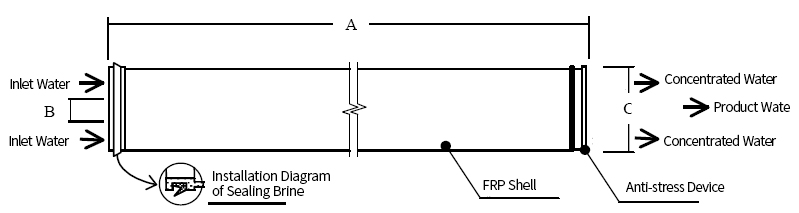

Membrane Element Figure

Limited Operation

Product Model |

HG-CW |

Max Operating Pressure |

600psi |

Typical Operating Pressure |

225psi |

Pressure Drop of Single Membrane |

<12psi |

Recovery Rate

|

15% |

Max Operating Temperature |

50℃ |

Max Cleaning Temperature |

50℃ |

PH Range of Continuous Working |

4.0-11.0

|

PH Range of Cleaning |

2.0-11.5

|

Allowable Max Contents of Residual Chlorine |

500ppm-h |

Inlet Water |

NTU<1 |

SDI<5 |

Information about Storage

Before the first use, all membrane elements must be stored under the original packaging conditions.

Store in a cool, dry and the place where is not directly exposed to sunlight or artificial lighting. Storage temperature stays at 0℃ to 30℃, and the longest storage time is 6 months.

HG series Seawater Desalination Membrane

Function and Identity

HG seawater desalination membrane element developed by AMESTEC is a standard membrane element with the highest pressure bearing capacity in the world. It has the characteristics of high removal rate of sodium chloride and removal rate of boron. It is widely used in the field of desalination of seawater and desalination of brackish water.

Product Specification

Table 1 Parameters of Membrane

|

Product |

Effective Area ft2(m2) |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-OW10 |

375(34.8) |

6000(22.7) |

99.7% |

|

HG-OW20 |

400(37.2) |

6400(24.2) |

99.7% |

|

HG-OW10-AD |

375(34.8) |

6400(24.2) |

99.7% |

|

HG-OW20-AD |

400(37.2) |

7000(26.5) |

99.7% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test Condition: Solution of 32,000ppm NaCl, 800psi of operating pressure, 25℃ of temperature, pH7, 8% of recovery rate.

Membrane Element Figure

Limited Operation

Product Model |

HG-OW |

Max Operating Pressure |

1200psi |

Typical Operating Pressure |

800psi |

Pressure Drop of Single Membrane |

<20psi |

Max Operating Temperature |

50℃ |

Max Cleaning Temperature |

50℃ |

PH Range of Continuous Working |

2.0-11.0

|

PH Range of Cleaning |

1.0-12.0

|

Inlet Water |

SDI<5 |

Information about Storage

Before the first use, all membrane elements must be stored under the original packaging conditions.

Store in a cool, dry and the place where is not directly exposed to sunlight or artificial lighting. Storage temperature stays at 0℃ to 30℃, and the longest storage time is 6 months.

General Information

- Once the membrane element is wetted, it must always be wet.

- Due to the actual problems caused by the user's failure to strictly abide by the operating restrictions and guidelines set in this Code, our promised limited warranty will be invalid.

- Long-term shutdown to prevent microbial growth, we suggest that the membrane elements into the protection liquid statics.

- If the user uses incompatible chemicals and lubricants to cause improper impact on the original, should bear the corresponding responsibility.

- The maximum allowable pressure drop for a single pressure vessel is 60PSI(4.1bar).

- Avoid back pressure on the water side of the product at all times, so as not to cause bad problems.

Home

Home Project

Project Contact Us

Contact Us Tel

Tel