Regular Nanofiltration Spiral-wound Membrane

The HGNF regular Nanofiltration spiral-wound membrane of AMESTEC adopts the proprietary composite membrane, and the molecular weight of uncharged organic molecules is about 150-300 Dalton. They allow monovalent salts to pass through and divalent salts will be retained.

Table 1 2540 Membrane elements

|

Product |

Effective Area ft2(m2) |

Inlet Channel Width |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-NF81-2540 |

24(2.2) |

31(0.79) |

520(2) |

98% |

|

HG-NF82-2540 |

18(1.7) |

47(1.19) |

400(1.5)

|

98% |

|

HG-NF83-2540 |

28(2.6) |

31(0.79) |

600(2.3) |

98% |

|

HG-NF84-2540 |

22(2) |

47(1.19) |

500(1.9) |

98% |

|

HG-NF91-2540 |

24(2.2) |

31(0.79) |

650(2.5) |

96% |

|

HG-NF92-2540 |

18(1.7) |

47(1.19) |

500(1.9) |

96% |

|

HG-NF93-2540 |

28(2.6) |

31(0.79) |

750(2.8) |

96% |

|

HG-NF94-2540 |

22(2) |

47(1.19) |

600(2.3) |

96% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test condition: 2,000mg/L MgSO4 solution, 110psi operating pressure, temperature of 25℃, the recovery rate of 15%.

Table 2 4040 Membrane elements

|

Product |

Effective Area ft2(m2) |

Inlet Channel Width |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-NF81-4040 |

90(8.4) |

31(0.79) |

1950(7.4) |

98% |

|

HG-NF82-4040 |

68(6.3) |

47(1.19) |

1450(5.5)

|

98% |

|

HG-NF83-4040 |

87(8.1) |

31(0.79) |

1900(7.2) |

98% |

|

HG-NF84-4040 |

68(6.3) |

47(1.19) |

1450(5.5) |

98% |

|

HG-NF91-4040 |

90(8.4) |

31(0.79) |

2450(9.3) |

96% |

|

HG-NF92-4040 |

68(6.3) |

47(1.19) |

1850(7) |

96% |

|

HG-NF93-4040 |

87(8.1) |

31(0.79) |

2350(8.9) |

96% |

|

HG-NF94-4040 |

68(6.3) |

47(1.19) |

1850(7) |

96% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test condition: 2,000mg/L MgSO4 solution, 110psi operating pressure, temperature of 25℃, the recovery rate of 15%.

Table 3 8040 Membrane elements

|

Product |

Effective Area ft2(m2) |

Inlet Channel Width |

Average Flow Rate GPD(m3/d)

|

Average Retention Rate |

|

HG-NF81-8040 |

8200(31) |

375(34.8) |

31(0.79) |

98% |

|

HG-NF82-8040 |

6600(25) |

300(27.9) |

47(1.19)

|

98% |

|

HG-NF83-8040 |

8000(30.3) |

365(33.9) |

31(0.79) |

98% |

|

HG-NF84-8040 |

6250(23.7) |

285(26.5) |

47(1.19) |

98% |

|

HG-NF91-8040 |

10300(39) |

375(34.8) |

31(0.79) |

96% |

|

HG-NF92-8040 |

8200(31) |

300(27.9) |

47(1.19) |

96% |

|

HG-NF93-8040 |

10000(37.9) |

365(33.9) |

31(0.79) |

96% |

|

HG-NF94-8040 |

7800(29.5) |

285(26.5) |

47(1.19) |

96% |

Note: The average desalination rate will be tested after 24 hours. Fluctuation range of flow for a single membrane could be +25%/-25%.

Test condition: 2,000mg/L MgSO4 solution, 110psi operating pressure, temperature of 25℃, the recovery rate of 15%.

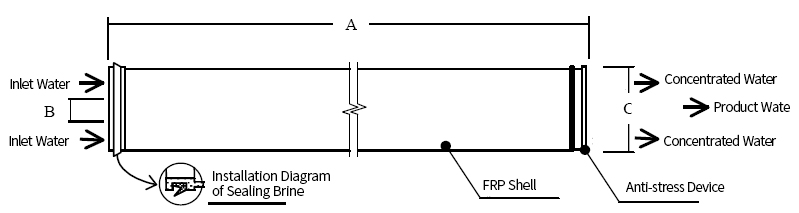

Membrane element figure

Limit operation

Product Model |

HG-NF8 |

HG-NF9 |

Max Operating Pressure |

600psi |

600psi |

Pressure Drop of Single Membrane |

<12psi |

<12psi |

Recovery Rate

|

15% |

15% |

Max Operating Temperature |

50℃ |

50℃ |

Max Cleaning Temperature |

50℃ |

50℃ |

PH Range of Continuous Working |

3.0-9.0 |

3.0-9.0 |

PH Range of Cleaning |

2.0-10.5 |

2.0-10.5 |

Allowable Max Contents of Residual Chlorine |

500ppm-h |

500ppm-h |

Inlet Water |

NTU<1 |

NTU<1 |

SDI<5 |

SDI<5 |

Storage Conditions

1. Before the first use, all membrane elements must be stored under the original packaging conditions.

2. Store in a cool, dry and the place where is not directly exposed to sunlight or artificial lighting. Storage temperature stays at 0℃ to 30℃, and the longest storage time is 6 months.

General conditions

· Once the membrane element is wetted, it must always be moist.

· Due to the fact that the user has not strictly complied with the operational restrictions and guidelines set by this specification, our limited warranty will be invalid.

· The system has been down for a long time to avoid the microorganism grows, we suggest putting the membrane element in the protection liquid.

· If the user USES incompatible chemicals and lubricants to cause undue influence on the original, he/she shall bear the corresponding responsibility.

· The maximum allowable pressure drop for a single pressure vessel is 60 psi (4.1bar).

· Whenever you should avoid the backpressure of the product water side, in case of adverse problems.

Home

Home Project

Project Contact Us

Contact Us Tel

Tel